Sense Cables

Detail

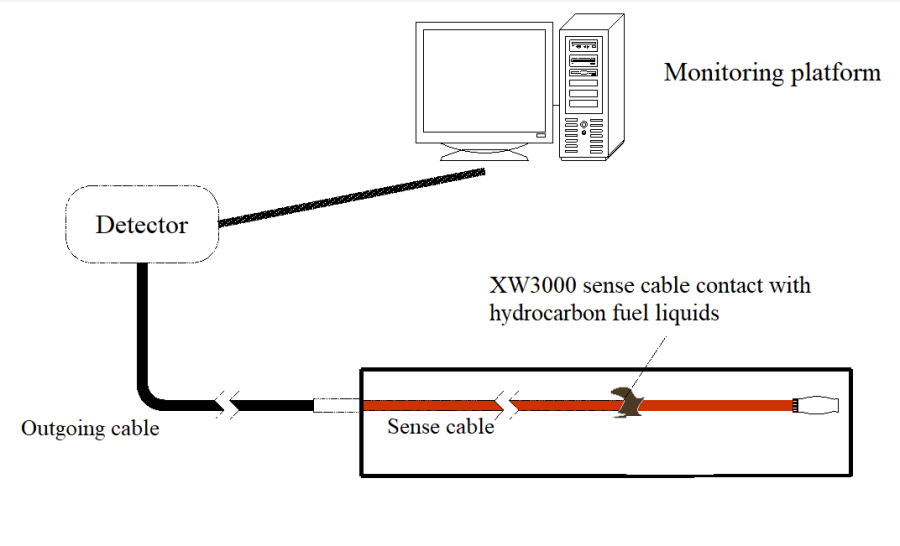

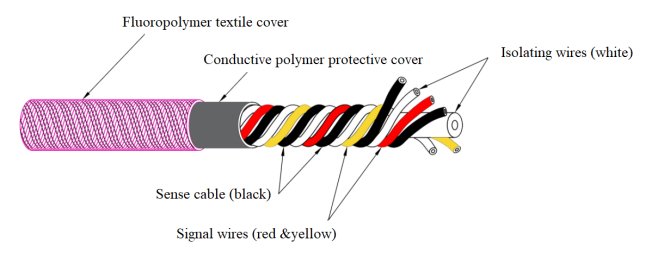

Product OverviewXW3000 Locating fuel Sensing cable can detect hydrocarbon fuel liquids anywhere on the cable. It can be connected with XW non-locating leak detector to form a leak detection system with high detection sensitivity, rapid and reliable response. The internal structure of the sense cable is similar to that of the water, acid and base liquid leak sense cable, but its surface is wrapped by a layer of conductive polymer protective cover, and the outermost layer is also a layer of fluoropolymer textile layer. Suitable for all kinds of places where there is risk of leakage of hydrocarbon fuel liquid, which is of great significance to energy saving and environmental protection.

Application & Features

Oil pipeline

Jet fuel pipeline

Diesel generator room

Oil storage pipeline

Oil storage tank

Oil pump

FeaturesFlexible for installation in complex and bending pipelines

The sense cable reacts quickly with the hydrocarbon fuel liquid, and the alarm can be triggered in a short time.

The sense cable does not react with water, which completely solves the problem of false alarms caused by touching water.

As a one-time product, sense cable is irreversible after reacting with the hydrocarbon fuel liquid and needs to be replaced in time.

The resistance is uniform and the error is within 1%. With high stability and accuracy of detection and locating for the leakage detection system which takes resistance as an important parameter.

Waterproof structure of the plastic plug, convenient cascade and expand detection range. Variety of length meet the needs of detection ranges.

Technical Data

Cable diameter

7.0mm

Sense cable

2*30AWG with conductive fluoropolymer protective cover

Continuity detection wire and signal wire

2*26AWG with conductive fluoropolymer insulation

Material(Central axis)

Fluoropolymer

Cable weight

500g/15m±10 g/15m

Wire core quantity

4pcs

Cable resistance

13Ω/m

Abrasion performance

65 cycles

Tensile

≤90kg

Operating temperature

-20℃~85℃

Alarm leakage(tap water)

Any position along the leakage sense cable: maximum 30mm

Operating temperature

Room temperature 20℃: gasoline (15 minutes), #1 diesel (1 hour), #2 diesel (2 hours), xylene (30 minutes)

Product Selection

When the sensing cable is in contact with the liquid hydrocarbon fuel, it penetrates into the conductive rubber layer through the outer textile protective cover, causing it to shrink. The core wires that were originally spirally arranged in parallel are all short-circuited due to shrinking and clinging to the conductive rubber layer, so that the current changes. According to the proportional relationship between the resistance and the length of the conductor, alarm signal is issued through the rapid calculation of the detector, figuring out the specific leak location.

Schematic diagram of operation principle