Sense Cables

Detail

Product OverviewXW1000C Discoloration water sense cable can detect leaking points anywhere on the cable which suitable for all kinds of liquid leakage risk places due to its cost-effective. It can be connected with XW non-locating leak detector to form a leak detection system with high detection sensitivity, rapid and reliable response. The sense cable is made of two light high-density polyethylene wires pressed around the central axis of the spiral. Compared with parallel structure wires, the spiral structure can reduce environmental electromagnetic interference and false alarm rate, and greatly improve the strength and service life of the cable. The woven protective cover design for wire cores, which can effectively prevent electrostatic interference, and the woven protective cover changes color when contact to water, which can intuitively determine the leakage location. The sense cable has automatic recovery function and can be reused.

Application & Features

Water supplying pipeline

Data Centre

IDC

Intelligent Building

Warehouse

FeaturesFlexible for installation in complex and bending pipelines

The woven protective cover design for wire cores, which can effectively prevent electrostatic interference, and the woven protective cover changes color when contact to water, which can intuitively determine the leakage location.

The resistance is uniform and the error is within 1%. With high stability and accuracy of detection and locating for the leakage detection system which takes resistance as an important parameter.

Waterproof structure of the plastic plug, convenient cascade and expand detection range. Variety of length meet the needs of detection ranges.

Spiral structure not only reduce the environmental electromagnetic interference and false alarm, but also greatly improve the strength and service life.

Technical Data

|

Cable diameter |

6.0mm |

|

Sense cable |

2*30AWG with conductive fluoropolymer protective cover |

|

Cable color(Central axis) |

Yellow |

|

Wire corequantity |

4pcs |

|

Cable weight |

500g/15m±10 g/15m |

|

Cable resistance |

13Ω/m |

|

Abrasion performance |

65 cycles |

|

Tensile |

≤90kg |

|

Operating temperature |

-20℃~75℃ |

|

Fire resistance |

V0 |

|

Alarm leakage (tap water) |

Any position along the leakage sense cable: maximum 30mm |

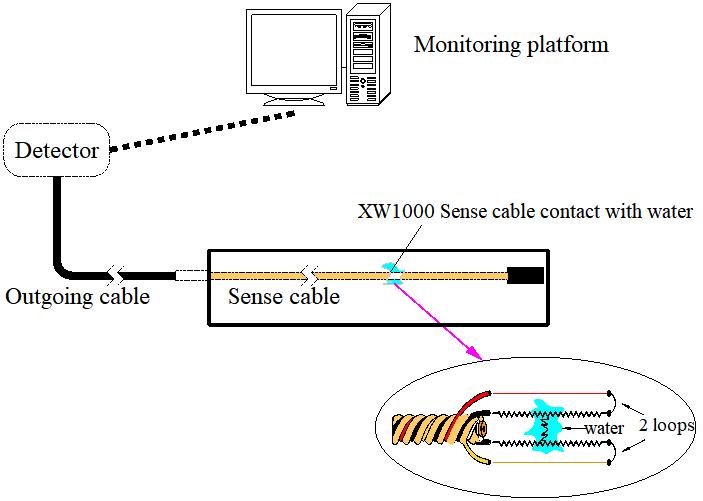

Operation Principle

When there is liquid in contact with sense cable, the inner core wires of the two sense wires are conductive in contact with liquid to form a loop resistance, so that the current changes. According to the proportional relationship between the resistance and the length of the conductor, alarm signal is issued through the rapid calculation of the detector, figuring out the specific leak location.

Schematic diagram of operation principle