Sense Cables

Detail

Product OverviewXW-TFDW30 Film water sense cable can detect leaking points anywhere on the cable which suitable for leak detection in highly clean environment and pipeline. It can be connected with XW non-locating leak detector to form a leak detection system with high detection sensitivity, rapid and reliable response. With thin film design, the sense cable can be installed close to the floor, and do not take up too much space. The sense cable has automatic recovery function and can be reused.

Application & Features

Semiconductor plant

Dangerous chemical factory

Cleanroom

Liquid pipeline

Panel factory

FeaturesFlexible for installation in complex and bending pipelines

Waterproof structure of the plastic plug, convenient cascade and expand detection range.

The resistance is uniform and the error is within 1%. With high stability and accuracy of detection and locating for the leakage detection system which takes resistance as an important parameter.

It's easy to install and does not affect the movement of people and trolley due to the thin film design with double-sided adhesive. And its smooth design features facilitate fast drying.

Technical Data

|

Cable Size |

28mm*0.35mm |

|

Material |

Alloy+PET |

|

Cable color(Central axis) |

Yellow |

|

Wire core quantity |

4pcs |

|

Cable weight |

112g/15m±2g/15m |

|

Cable resistance |

13Ω/m |

|

Abrasion performance |

65 cycles |

|

Tensile |

≤0kg |

|

Operating temperature |

-20℃~110℃ |

|

Fire resistance |

V0 |

|

Alarm leakage (tap water) |

Any position along the leakage sense cable: maximum 0mm |

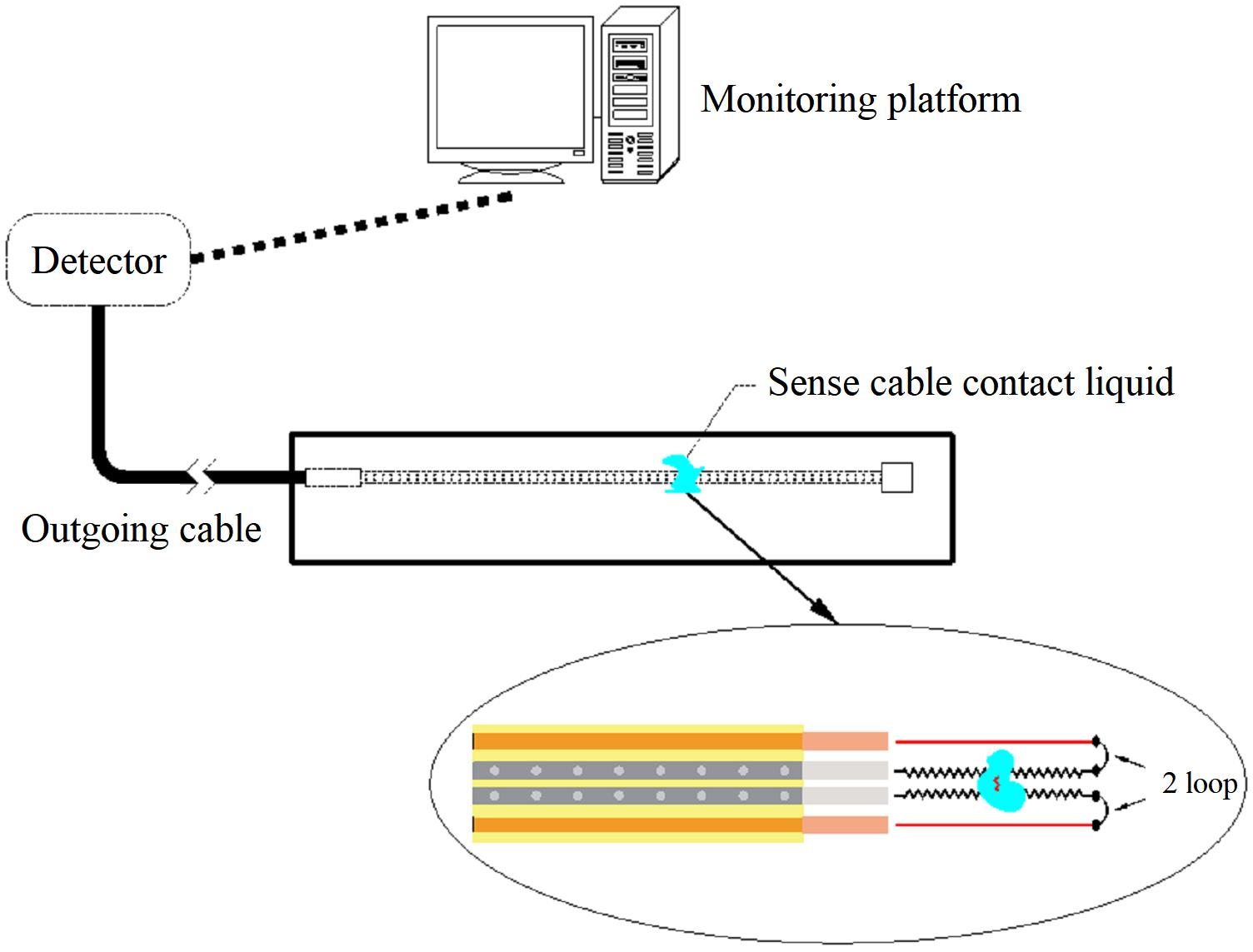

Operation Principle

When there is liquid seep into the interior through small holes on the surface of sense cable, the inner core wires of the two sense wires are conductive in contact with liquid to form a loop resistance, so that the current changes. According to the proportional relationship between the resistance and the length of the conductor, alarm signal is issued through the rapid calculation of the detector, figuring out the specific leak location.

Schematic diagram of operation principle